Retrofitting Buildings for Energy Efficiency

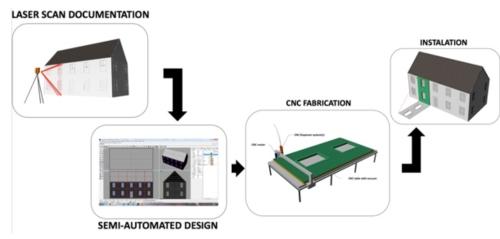

In the United States today, 40% of all energy is consumed by insulated buildings. To improve the insulation of buildings, a new technology at Worcester Polytechnic Institute has been developed known as Retrofitting Buildings for Energy Efficiency. Retrofitting Buildings for Energy Efficiency utilizes a unique four step process to provide custom- built insulation that is attached to the outside of a building as shown in the figure below:

The first of the four steps starts by scanning an entire building with lasers. Second, the laser scan documentation is then analyzed and entered into a computer model. Using the computer model, each custom-fit panel is then fabricated. Lastly, the custom-fit panels are easily installed piece by piece to create an air-tight finish on the building and improve the insulation.

Unlike any other processes on the market, Retrofitting Buildings for Energy Efficiency provides custom-fabrication and is tailored to each building. Additionally, the process is the first to stream-line pre- fabrication directly to delivery, limiting the number of site visits. This stream-lined process results in high performance insulation that is less costly than current options on the market for new and old buildings that ultimately leads to more energy efficient buildings.

Key Features/Benefits

- Improves insulation for new and old buildings.

- Creates an air-tight seal.

- Stream-lined delivery process.

- More energy efficient buildings.