High Performance Electrode Manufacturing Method

Manufacturing of lithium-ion (Li-ion) batteries directly influences their performance. Current manufacturing methods includes a slurry coating process for electrodes that create a microstructure framework. After slurry coating, the electrodes need be dried to remove the solvent. This microstructure framework provides ion transfer pathways between the coating materials. These pathways are crucial for battery survival during handling, packaging, and use. During manufacturing, there is a trade-off between production efficiency and high drying rate. Drying rate refers to the pathway-capable parts of the electrode coating.

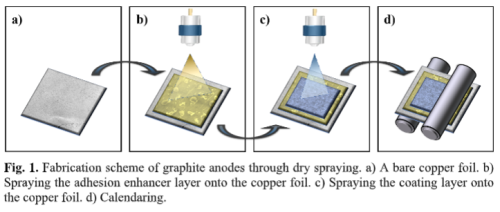

This invention proposes the addition of a graphite dry spraying of electrodes during their manufacturing. Various other materials are mixed with the graphite and dry sprayed onto the electrode. Using this procedure, manufacturers no longer need to wait for materials to dry. Further, microstructure conditions and physical properties are improved by using this dry spraying. Therefore, this method creates for a high-efficiency, scalable, and low drying rate manufacturing process.

Key Features/Benefits

- Completely remove the electrode drying process

- Allows for advanced microstructure design

- Scalable to high-production environments