Two faculty members from Worcester Polytechnic Institute (WPI) have received the National Science Foundation’s CAREER Award, the most prestigious NSF award for faculty members early in their careers as researchers and educators. The awards, to Sonia Chernova, assistant professor of computer science and robotics engineering, and Diana Lados, assistant professor of mechanical engineering, bring to 18 the number of current WPI faculty members who have received the honor.

"We congratulate Professors Chernova and Lados on earning these exceptional awards," said WPI Provost Eric Overström. "With these grants, they will undertake important work with the potential to bring about significant advances in their respective fields and profound improvements in our quality of life. Through the CAREER Award, the NSF recognizes young faculty with exceptional promise. I don’t believe it could have selected two more fitting recipients."

Paving the Way for General Purpose Robots for Everyday People

Sonia Chernova has received a five-year, $500,000 CAREER Award for research that will help pave the way for general purpose robots that can work effectively and productively alongside people in everyday settings. Such robots will be able to adapt easily to take on new jobs and respond to the changing needs of their human partners—for example, performing routine housekeeping tasks to help the elderly continue living in their own homes or enabling small manufacturers to quickly gear up to make new products without having to employ a staff of programmers. The need to accelerate the development of such robots was an important element of the robotics research roadmap presented to Congress in 2009 by the Computing Community Consortium and the National Robotics Initiative announced by President Obama in 2011

Chernova argues that to realize this vision, the way robots are taught to perform tasks has to fundamentally change. "Currently, we attempt to preprogram all of the knowledge a robot needs to operate in our world," she says. "In this way, we’ve been successful at developing robots to work in constrained environments, such as assembly lines. But we have not been so successful at getting robots to work in natural, unconstrained environments, such as homes. To enable robots to adapt to new and changing environments, we need a way to customize a robot’s behavior on the fly, without the need for skilled programmers."

With her CAREER Award, Chernova will attempt to determine what robots need to know to perform various tasks and how everyday people, with no understanding of programming or even how robots work, can help them gain that knowledge. To accelerate this research, she’ll draw on the power of crowd-sourcing—creating a web-based testing environment that will enable her to gather data from thousands of Internet users. Designed as a game in which players advance through progressively more difficult tasks—first with a simulated robot and later, after they’ve achieved sufficient proficiency, with a physical robot—the system will ask users to show a robot how to perform tasks in a home (tidying up a room, for example) and in a small-scale manufacturing plant.

Unlike typical robots, the machines used in Chernova’s research will be capable of active learning, which means that they will be able to ask questions. Since her aim is to develop robots that operate in proximity with people, it makes sense, she says, for the robots to ask people for help. In particular, the robots will be able to ask which features of objects or of the environment are relevant to a particular task—for example, whether color is important in determining whether an object on a table is a book or a magazine. "People are excellent at ruling out irrelevant features and knowing what is important and what isn’t," Chernova says. "Developing similar capabilities for robots is critical to enable them to operate effectively in our complex world."

Developing Tools to Accelerate the Use of Light Metals in Transportation

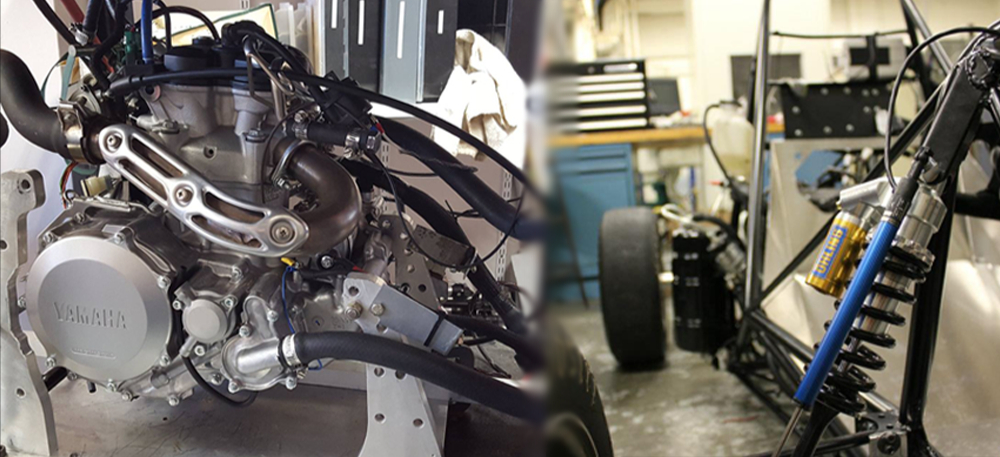

Diana Lados has received a five-year, $525,000 CAREER Award for a study aimed, ultimately, at increasing the use of lightweight metals like aluminum, titanium, and magnesium in cars, trucks, airplanes, boats, and other transportation applications.

Increasing the use of light metal alloys in cars, for example, will have important economic and environmental benefits, since each 10 percent reduction in vehicle weight results in a 5 to 7 percent increase in fuel economy, along with a concomitant decrease in greenhouse gas emission. In fact, Lados says, replacing steel and cast iron with lighter metals may be essential if auto makers are to meet the EPA’s ambitious new target of increasing the corporate average fuel economy (CAFE) standard for all new cars and light-duty trucks to 54.5 miles per gallon by 2025.

To significantly increase the use of light metals in the transportation sector, Lados says it will be necessary, first, to close a significant gap in our understanding of these metals and their susceptibility to developing cracks that can lead, ultimately, to the failure of metal parts. "Light metals are not currently used as extensively as they could be or to their highest potential in cars and airplanes because of limitations in our fundamental understanding of these materials and in our ability to accurately predict their life," she says. "My goal is to develop new methods and tools that will enable engineers to design materials and structural components with confidence."

The new methods and tools will be built upon on a new, mechanistic understanding of crack formation and propagation in various light metals. Through systematic laboratory studies and the use of analytical methods and computational modeling, Lados will explore how tiny cracks form in the microstructure of a metal part and how those small cracks propagate, turning into larger, even visible cracks and, ultimately, producing metal failure by fatigue. Fatigue is a critical design consideration, especially in structural applications, as more than 90 percent of all mechanical failures are fatigue related.

This research will also bridge a knowledge gap that exists between mechanical engineering and materials science by complementing fracture mechanics approaches (which include tools for predicting the propagation of large cracks) with materials science knowledge (which makes much-needed connections between a metal’s micro-/nano-structure and small crack behavior). If unresolved, this gap leads to uncertainties about the true susceptibility of metals to cracking and failure under real-world conditions. This, in turn, leads designers to build excessive safety factors, and, therefore, excess weight, into parts, reducing the fuel-saving benefit of using light metals.

The new tools Lados will develop will enable designers to more accurately predict the lifespan of light metals used in high-integrity, fatigue-critical applications, while also permitting metals producers to develop new alloys and processes designed for current and future applications where light metals are not extensively used today. To accelerate the verification and adoption of the new methods and tools, Lados will work with the more than 20 members of WPI’s Integrative Materials Design Center, which she founded and directs. The membership includes major transportation manufacturers, including Chrysler, Honda, Harley-Davidson, Caterpillar, Boeing, Sikorsky, and Mercury Marine, along with leading metals producers, including Rio Tinto Alcan.

"They will take our tools and techniques and apply them with the materials they use every day," Lados says. "In this way, we will be able to validate these developments on a broad spectrum of materials and get them into widespread use more quickly and effectively."