A new collaboration between Worcester Polytechnic Institute’s Biomanufacturing Education and Training Center (BETC) and Pennsylvania single-use process component manufacturer AdvantaPure/NewAge Industries marks the expansion of programming at the center to help companies that serve the biomanufacturing industry.

Since its inception, the BETC has worked primarily with companies like Biogen Idec, Shire, Bristol-Myers Squibb, Pfizer, and others to provide customized training programs for their employees who manufacture biologic medicines. The collaboration with AdvantaPure extends the center’s capabilities to help companies that supply equipment and solutions to biomanufacturers.

"Working with companies that develop and manufacture biologics remains a core focus of our center, but we also recognize there are many layers of the biomanufacturing industry that we can help," said Kamal Rashid, PhD, director of the BETC and research professor at WPI. "Our new relationship with AdvantaPure is a terrific example of how our center can work effectively with equipment manufacturers, which are a vital element of this growing industry."

AdvantaPure makes high-quality tubing, hoses, manifolds, and other products used by biomanufacturers. Rashid and AdvantaPure CEO Ken Baker first broached the idea of a customized training program at the BETC in early 2014 when they met at an industry conference. "We are a company that invests a lot of time and resources into educating our team members," Baker said. "We have a lot of people who interact with customers and we want them to have a better understanding of the biomanufacturing process and how customers use our products."

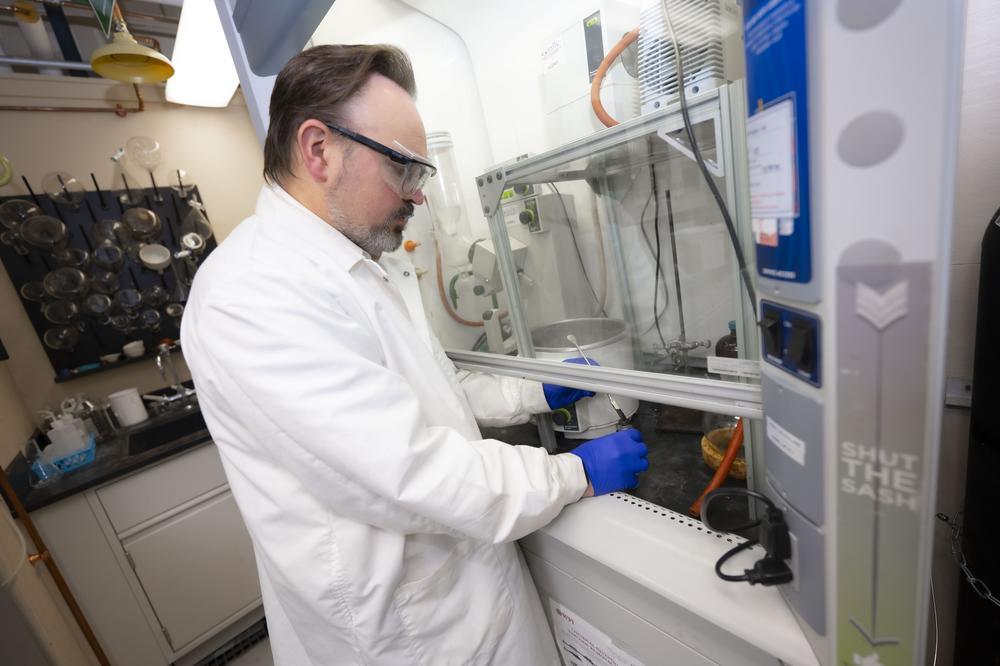

Over the summer of 2014 AdvantaPure and BETC staff continued the discussion and developed a customized program to expose AdvantaPure team members to all facets of biomanufacturing. Then, in November, Baker personally led a delegation of 19 people from AdvantaPure who boarded a bus in Southampton, Penn., and headed north to Worcester for an accelerated program on the fundamentals of biomanufacturing with single-use systems. The group included staff from the company’s manufacturing, administrative, marketing, sales, quality, and purchasing departments.

"It was an excellent experience and a nice balance between classroom and hands-on training. We really got the feel for the processes and the many steps that it takes to make a biologic," Baker said. "We believe the more we understand about our clients’ business, the better we can serve them. So, now, when someone starts talking about chromatography, our people know what that means and where it fits in the process."

During the training program, discussions among company and BETC staff generated an intriguing question about some of the company’s technology. AdvantaPure is one of a few companies that have developed technology to overmold manifold connections, replacing standard "barbed" connections widely used to join tubing sets. The smooth molded connection was designed to prevent leaks and contamination. At the BETC, however, instructors speculated there may be additional inherent benefits to the technology. "We hadn’t considered those possible benefits, so we have decided to partner with the BETC to investigate the idea," Baker said.

In early 2015 AdvantaPure will fund a small-scale study at the BETC to investigate the potential benefits to their overmolded technology. The company is also donating several other products and systems for the BETC to integrate into its bioprocessing equipment for use in other training programs. "We look forward to the staff’s feedback on our products," Baker said. "I believe this is the beginning of an important relationship for us with WPI."

Funded in part by a grant from the Massachusetts Life Sciences Center, the BETC is a multi-faceted resource for the biologics industry, providing a range of hands-on customized programs. The BETC works with biomanufacturers to help them train, and retrain, their employees at a state-of-the-art center removed from their own production facilities. The center also offers a range of consulting services to help companies deal with challenges or institute best practices in their operations.

"Biomanufacturing is growing significantly in the United States and around the world, and the technology used to make biologics is evolving. By working with manufacturers like AdvantaPure and others, we increase WPI’s impact across the supply chain," Rashid said.

About the Biomanufacturing and Training Center at WPI

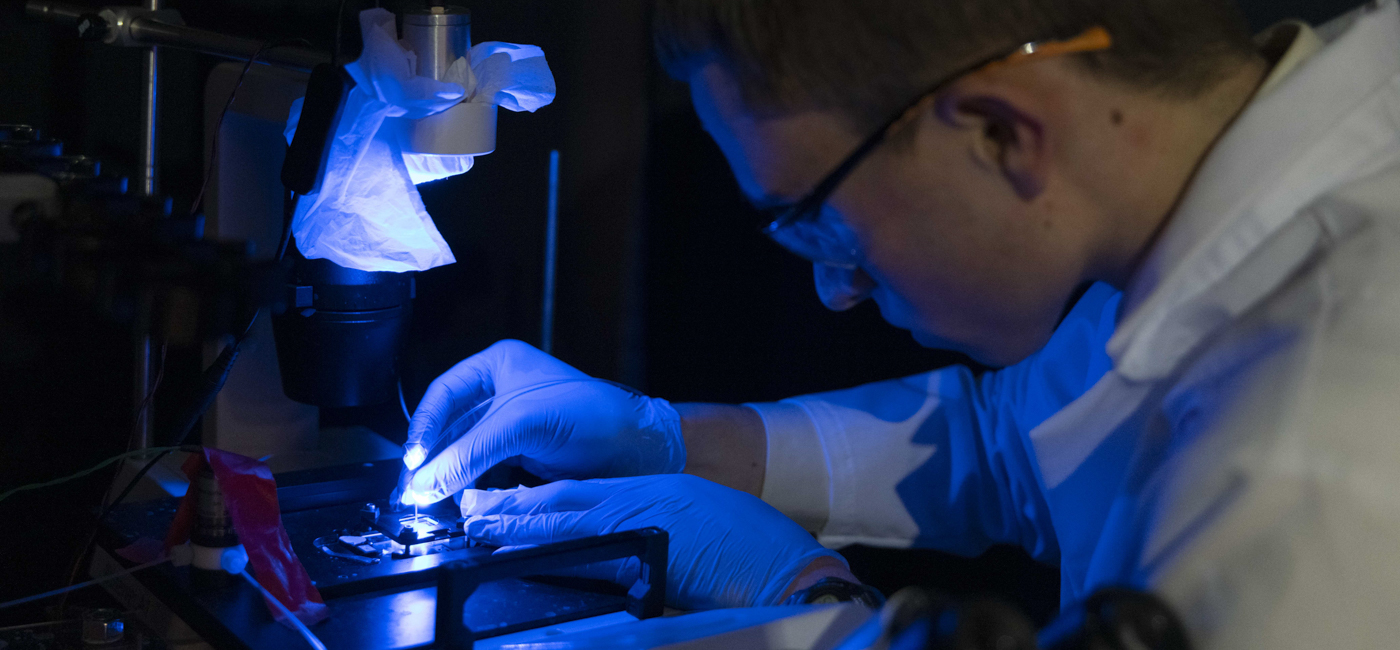

The BETC is a 10,000-sq.-ft. fully functional bench- to pilot-scale biomanufacturing center. It has large- and small-scale bioprocessing areas for microbial fermentation, and mammalian and insect cell culture production. The center also features support labs and classrooms integrated with industry-standard process areas for equipment preparation, buffer and media preparation, product capture, purification, and analytics. It is equipped with single-use technologies as well as traditional autoclavable and stainless steel process equipment. The BETC curriculum spans multiple programs, including upstream and downstream processes, designed to help current biomanufacturing employees improve and expand their skills. The BETC also offers open-enrollment, nonproprietary programs for individuals in the industry seeking to advance, as well as a fundamentals course designed for people seeking entry to the field. The center is also a resource for graduate and undergraduate education at WPI.