WPI and Colorado School of Mines (Mines) have established the first research center in the nation dedicated to developing new technologies for maximizing the recovery and recycling of metals used in manufactured products and structures. Called the Center for Resource Recovery and Recycling (CR3) and funded by a five-year, $400,000 award from the National Science Foundation, the new center (to be located at both WPI and Mines) will promote a more sustainable approach to the use of metals in the United States with the aim of dramatically reducing the energy usage and the carbon footprint associated with their production.

The NSF award will fund the cost of establishing the center and recruiting corporate members, who, representing the diverse and often fragmented metals supply chain, may include scrap yards, disassembling companies, municipal waste centers, shredding companies, smelters, foundries, and manufacturers. According to Diran Apelian, Howmet Professor of Mechanical Engineering at WPI and director of its Metal Processing Institute (MPI), the center will seek between 30 and 40 members, each initially paying $30,000 per year, bringing the potential funding for the center to more than $6 million over the course of the grant. Apelian will serve as the center’s director and WPI will be the lead institution; Brajendra Mishra, professor and associate director of the Advanced Coatings and Surface Engineering Laboratory and the Kroll Institute for Extractive Metallurgy at Mines, will serve as associate director.

"Despite growing efforts to recycle metals, we still fail to recover half of the post-consumer metal scrap generated in this country and we rely on primary metals--those derived directly from ores--to fulfill two-thirds of our manufacturing needs," Apelian said. "The environmental benefits of reusing scrap instead of smelting primary metal are tremendous. For example, if we could increase the recovery of aluminum scrap by just one percent, we would save 600 million kilowatt-hours of electricity and keep 130 million tons of carbon out of the atmosphere."

"Conserving and preserving materials, energy, and resources are the needs of the day for societal sustainability," said Mishra. "The generations to come require us to take on this responsibility. At the Colorado School of Mines, we are dedicated to the stewardship of earth, energy, and environment. The establishment of this new research center and its future accomplishments will endorse this commitment and dedication."

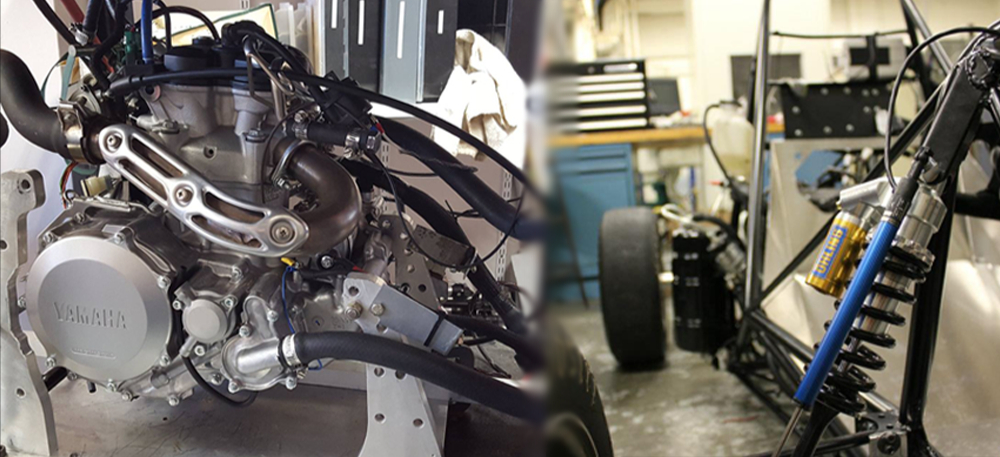

Faculty and students associated with CR3 will collaborate with industry partners to conduct research leading to advances in recycling and recovery technology that maximize the capture and reuse of post-consumer scrap and minimize the production of manufacturing scrap. These include sensors, controls, and sorting technologies that can identify valuable metals and separate them from the waste stream, as well as new alloys that are easier to recycle. WPI will focus its research on metals used in structural applications, such as steel used in buildings and aluminum forged for automotive components, while Mines will focus on metals used in functional applications, including high-value and rare-earth metals used in computers, electronics, and photovoltaics.

"Our nation’s economic health is intimately intertwined with our ability to conserve natural resources including inorganic materials, which are not renewable," Apelian said. "The issue of sustainability should be paramount in how we design, manufacture, use, and retire the many products we use. That is the motivation for this new center’s research and its partnership with industry."

Members of CR3 will be able to help determine the direction of and benefit from the center’s precompetitive research, and will have royalty-free rights to intellectual property resulting from that research. They will be able to work with university faculty and students and participate in graduate internship programs. In addition, members have the option of sponsoring supplementary research projects for additional fees. Members will have representation on the center’s Industrial Advisory Board, which will meet twice a year--once at WPI and once at Mines.

In addition to conducting research, CR3 will develop materials recycling and recovery curricula at WPI and Mines that will help prepare a workforce ready to meet the challenge of promoting sustainability in the materials industries. Both universities will also seek to broaden societal participation in the center. At WPI, these efforts will include continuing a seminar that engages first-year undergraduates in the challenges of sustainable development, integrating of sustainable engineering project work into a summer program for girls, and establishing a strategic alliance with the University of Puerto Rico, Mayaguez, to promote joint student projects and academic programs. At Mines, the educational and research activities of CR3 will be a vehicle for helping achieve a strategic objective of expanding the diversity of the graduate student population and the faculty.