WORCESTER, Mass.– January 26, 2009 – Diana Lados, assistant professor of mechanical engineering at Worcester Polytechnic Institute (WPI) and director of the university’s Integrative Materials Design Center (iMdc), has received the Orr Early Career Award from the Materials Division of the American Society of Mechanical Engineers (ASME). The award recognizes research excellence in specific areas of materials science: experimental, computational, and theoretical fatigue, fracture, and creep.

As part of the recognition, Lados received the Orr Best Paper Award for “Fatigue Crack Growth in Metallic Materials: Mechanisms and Design Considerations,” which she presented at the ASME 2008 International Mechanical Engineering Congress and Exposition in Boston in November.

“We are proud of Professor Lados and congratulate her on this well-deserved honor,” said John A. Orr, WPI’s provost and senior vice president. “Her work is already having a major impact. Materials science and engineering is an important part of WPI’s heritage, and is now more important than ever. Professor Lados exemplifies the high quality and exceptional talents of our young faculty members.”

Lados joined the WPI faculty in 2006 as a research professor in the university’s Metal Processing Institute (MPI) after completing her PhD in materials science and engineering at the university and holding postdoctoral and research scientist appointments at MPI. She also holds a BS and an MS in mechanical engineering from Polytechnic University of Bucharest and an MS in mechanical engineering from Southern Illinois University at Carbondale. She was named a tenure-track assistant professor of mechanical engineering in 2007.

Lados has published more than 40 journal articles and made more than 80 conference and industrial presentations on such topics as design and optimization of materials and processes for fatigue, fatigue crack growth, fracture resistance, fracture mechanics, residual stress, plasticity, solidification processing and heat treating, and aluminum foundry engineering. In addition to the Orr Award, her work has been recognized with a number of national and international honors, including the CPMT/Axel Madsen Award from the Center for Powder Metallurgy Technology, the Sigma Xi Graduate Research Scientific Award, the Aluminum Division Scholarship Award from the American Foundry Society, and the ASM Worcester Chapter Chester M. Inman Award.

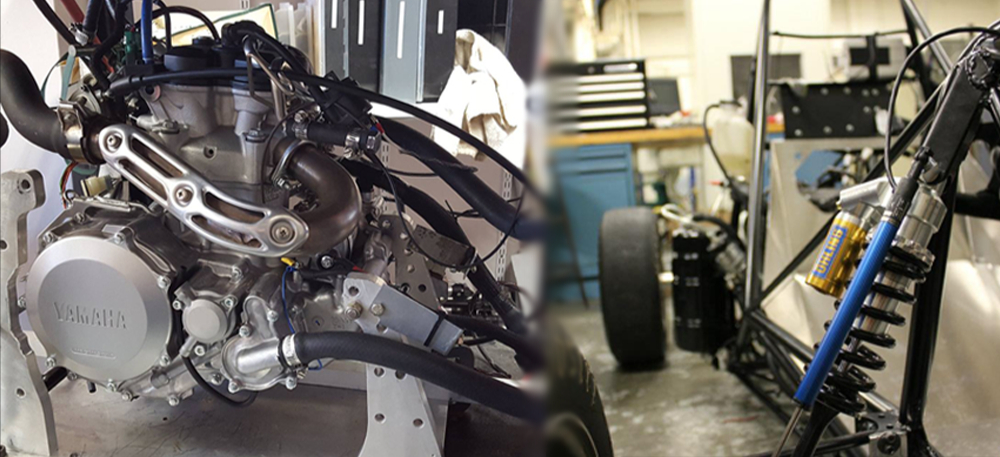

Lados’s research on materials processing and fatigue has produced significant research and development advancements at a number of corporations. For example, a new patented impact resistant aluminum-silicon cast alloy used in all aluminum propellers and the most technologically advanced outboard engine made by Mercury Marine resulted directly from her work. General Motors is using Lados’s research in the design of a new generation of engine blocks. And ASTM, the international standards organization, is recommending for implementation as part of the E647 standard, a new analytical tool for residual stress compensation developed by Lados.

In 2008, Lados built on her ties with industry to establish iMdc, an industry-government-university research and educational alliance dedicated to advancing the state of the art and practice in sustainable materials-process-component design and manufacturing for high-performance, reliability, and recyclability. The center has 17 corporate members and four supporting companies. Members include some of the world’s largest manufacturing companies, including Boeing, Caterpillar, General Dynamics, General Motors, Harley-Davidson, Honda, Pratt & Whitney, Sikorsky, and Textron Systems, as well as such governmental organizations as the U.S. Army Research Laboratory, Benét Laboratories, and NASA Langley.