A Worcester Polytechnic Institute (WPI) professor—in collaboration with national laboratories and a global auto parts supplier—is testing a new type of welding that may make the joint between light metal alloys more resistant to corrosion, including salt spray, leading to future designs of durable, next-generation metal car joints used in ultra-light car doors and other vehicle body applications.

Adam Powell, associate professor of mechanical engineering, was awarded a three-year, $1.5 million grant from the Department of Energy’s Office of Energy Efficiency and Renewable Energy’s Vehicle Technologies Office for the research. As the lead institution, WPI is receiving $750,000 while two other groups—Oak Ridge National Laboratory (ORNL) and Pacific Northwest National Laboratory (PNNL)—will split the remainder. Magna International will contribute in-kind time and materials to the project.

Powell said that the auto industry is seeking to reduce the weight of cars and trucks while maintaining the lifespan of a car. One of the ways to do that, he said, is to use advanced lightweight materials such as aluminum and magnesium alloys. The researchers are testing to determine if a new type of welding—known as friction stir welding—reduces corrosion in aluminum-magnesium alloy joints. Currently, any joint involving direct contact between different metals tends to suffer from galvanic corrosion.

“We’re trying to show that corrosion can be much less of a problem with this new type of welding,” said Powell, who is the principal investigator on the project. “We think that this process holds a lot of promise and could make a significant impact on energy use in motor vehicles without reducing the lifespan of a car.”

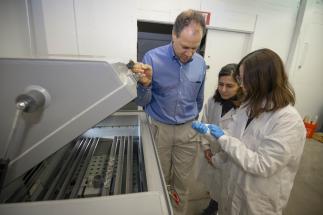

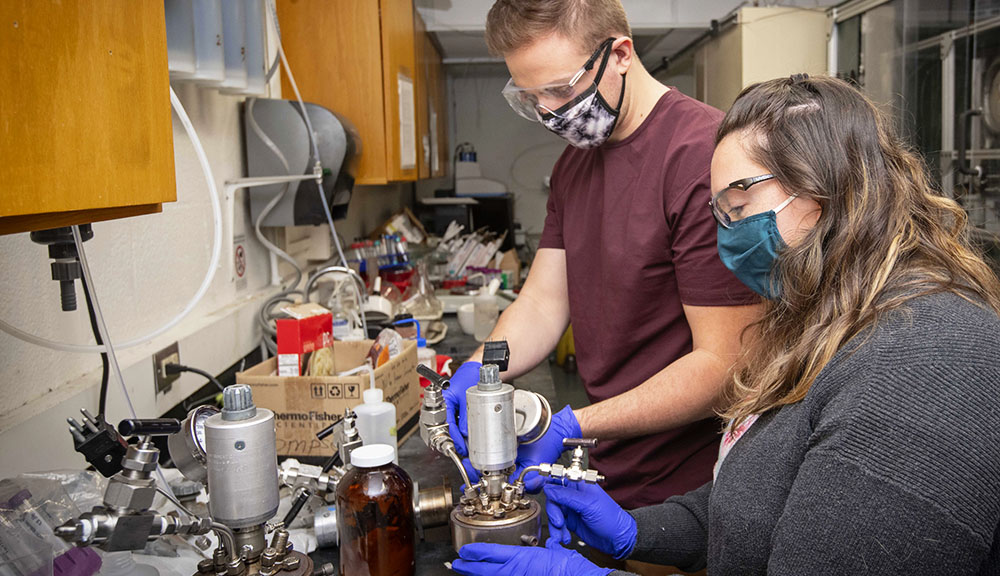

Under the research plan, Magna, a global mobility technology company and leader in lightweight vehicle structures, provides aluminum and magnesium metals to PNNL, which welds the materials. PNNL then ships the welded parts to WPI, which conducts corrosion and mechanical testing. WPI then sends much of its tested samples to ORNL, which oversees advanced analysis on the welds.

Computer simulations then take place at WPI, said Powell, “to try to understand how the corrosion and mechanical fracture work together.”