The Center for Heat Treating Excellence (CHTE) at Worcester Polytechnic Institute (WPI) and one of its members, GM Global Powertrain Engineering, have been awarded a patent by the United States Patent and Trademark Office for a method for predicting heat transfer coefficients for metal castings during quenching and cooling operations, an innovation that will help make cast parts more durable.

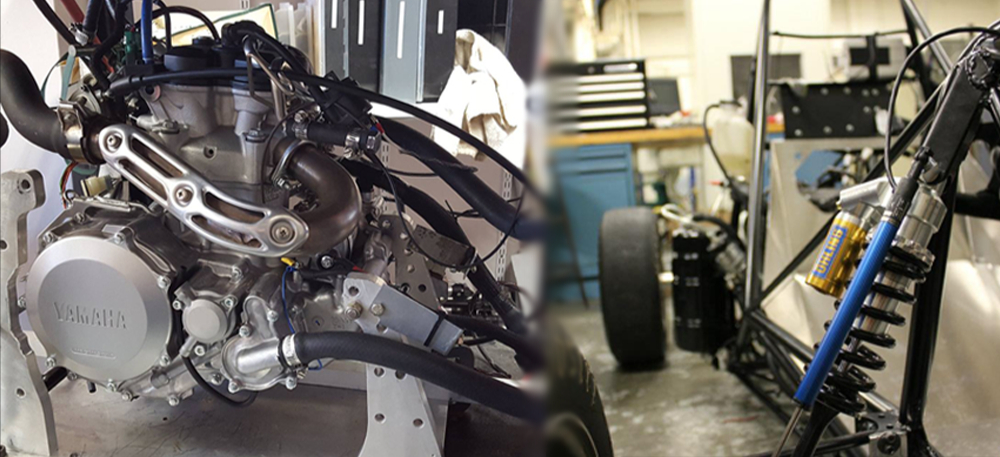

The research that formed the basis for the patent was funded by GM Powertrain and conducted in CHTE laboratories on the WPI campus and at GM Global Powertrain Engineering in Pontiac, Mich. It was part of GM’s initiative to model and analyze engines for better durability.

The inventors for the patent (U.S. Patent No. 8437991, "Systems and Methods for Predicting Heat Transfer Coefficients During Quenching") are:

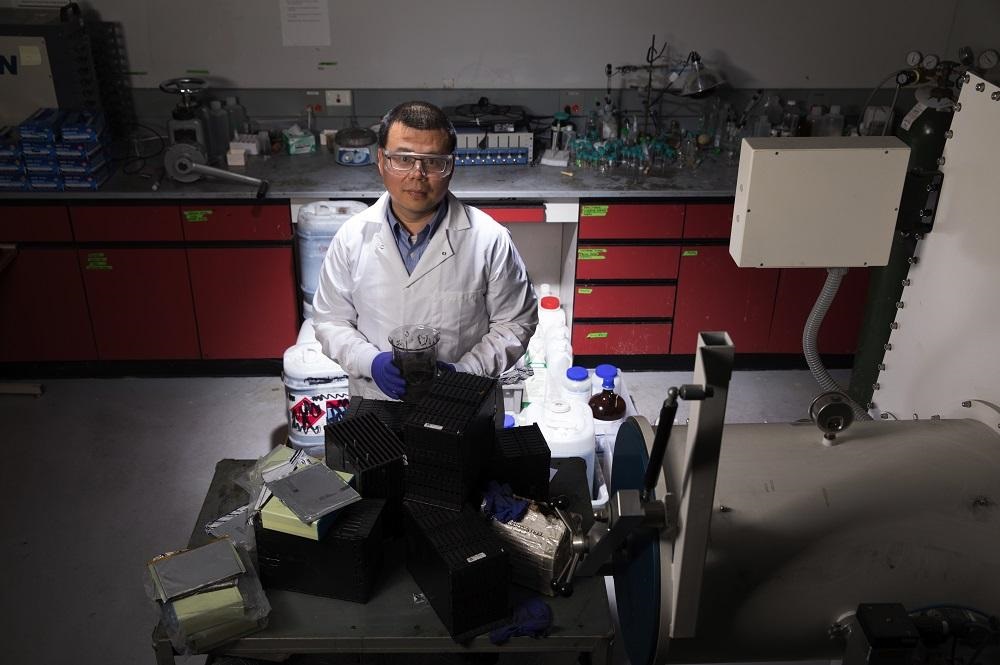

- Qigui Wang, PhD, GM Powertrain

- Bowang Xiao, PhD, GM Powertrain

- Gang Wang, PhD, associate professor at Tsinghua University in China (formerly a research scientist at WPI)

- Richard D. Sisson, PhD, George F. Fuller Professor of Mechanical Engineering at WPI and director of WPI’s Materials Science and Engineering Program

- Kevin Rong, PhD, professor of mechanical engineering at WPI

“The Center for Heat Treating Excellence has done a lot of work on quenching, and this project was a logical extension of our expertise," Sisson said. "It represents the good work of WPI students and faculty and CHTE member companies.”

Xiao was a PhD student at WPI when the patented methodology was developed. “We conducted a series of air quenching experiments, CFD (computational fluid dynamics) analysis, and FEA (finite element analysis) to model and predict temperatures and residual stresses in aluminum alloy casting during quenching," he said. "Residual stresses play an important role in engine durability performance, and the temperature history calculation for the casting is the key challenge for accurate residual stress prediction. For the first time, we integrated experimental results and CFD analysis into the FEA analysis to accurately and quickly predict heat transfer coefficients and temperature history.”

About the Center for Heat Treating Excellence

CHTE is an alliance between the industrial sector and university researchers to solve problems in the heat treating industry through collaborative research that addresses the industry’s short- and long-term needs. It provides an important forum where various segments of the industry pool their resources and advance the industry by developing the knowledge base and curricula for the education of its future leaders.