Lados’s research has been supported extensively by industry and government, including a five-year, $525,000 CAREER Award from the National Science Foundation (NSF), the agency's most prestigious award for young faculty members. Received in 2012, the award funded research aimed at developing a comprehensive mechanistic understanding of the initiation and propagation of fatigue-related cracks, along with unified fatigue-life predictive methods and computational tools. This work has helped accelerate the use of light metals in transportation applications, which can lead to greater structural performance and fuel efficiency, while reducing the greenhouse gas emissions.

Her other federal funding includes a $424,000 NSF award to develop a novel manufacturing process for lightweight metal-matrix nano-composites, work that earned her the 2011 Kalenian Innovation Award from WPI’s Collaborative for Entrepreneurship and Innovation and a patent development; funding from the U.S. Army and several national laboratories for original work on several advanced manufacturing technologies, including cold-spray processing and friction stir welding; and a $450,000 aviation grant to develop a new methodology for characterizing materials and damage using combined digital image correlation, electron backscattered diffraction, tomography, and other nondestructive evaluation techniques. Lados and her team have been at the forefront of research on additive manufacturing (AM) for nearly a decade having developed a fundamental understanding of the processing and properties of AM materials, along with building systematic databases and computational tools. These advances are helping expand the use of the technology in high-integrity structural applications and are providing a much-needed means for rapid product qualification and repair.

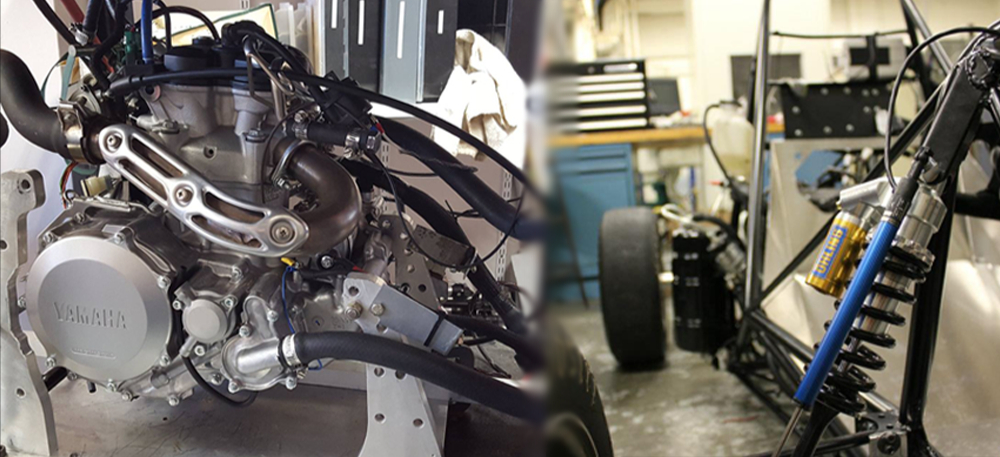

Work like this has benefitted from state-of-the-art technology she has obtained through two major equipment grants: a $467,000 Major Research Instrumentation award from the NSF for the acquisition of a system of high-speed cameras with quantitative stereo imaging and digital image correlation, and a $299,000 U.S. Army Research Office grant, through the highly competitive Defense University Research Instrumentation Program, for acquiring a sophisticated nondestructive evaluation system that provides unique capabilities for in-situ damage detection and crack monitoring in structural components. Her lab has also recently acquired advanced ultrasonic fatigue testing equipment through the collaboration with BOKU, making WPI one of just three universities in the United States with this unique and versatile system.

“This system will help us develop an original evaluation protocol that will change the future of selection and rapid qualification of materials fabricated by both conventional and advanced manufacturing technologies (e.g., additive manufacturing, cold spray, friction stir welding, and metal matrix nano-composites), leading to their faster adoption and confident use in high-integrity structural and elevated temperature applications in the transportation industries, defense, and many other sectors,” Lados said. “We are pioneering the use of this equipment for this purpose, while expanding our evaluation capabilities into the very high-cycle fatigue regime, which is difficult to achieve with traditional testing methods.”

The ASM and AΣM fellow honors follow Lados’s numerous national and international awards and distinctions, which include the inaugural Constance Tipper Silver Medal from the World Academy of Structural Integrity; the Silver Medal of the Society from ASM International, the society’s most distinguished honor for mid-career professionals; the Ralph R. Teetor Educational Award from SAE International; the Robert Lansing Hardy Award, the Early Career Faculty Fellow Award, and the Brimacombe Medalist Award from the Minerals, Metals & Materials Society (TMS). In 2012 Lados also launched a highly regarded symposium series on “Integrative Materials Design: Performance and Sustainability,” which she organizes every three years at the TMS annual meeting.

In 2010 Lados became the first WPI professor chosen by the National Academy of Engineering (NAE) to participate in the prestigious U.S. Frontiers of Engineering symposium for exceptional research; the NAE also selected her to participate in the Frontiers of Engineering Education symposium that same year for her significant innovations in teaching and learning. These programs represent the highest NAE recognition for U.S. researchers and educators under the age of 45. She was the only woman on a team of five leaders in her field selected in 2011 to participate in a Department of Energy program established to identify critical areas where materials science and engineering will shape research, business opportunities, and funding in the current decade.

Lados has also received WPI’s Sigma Xi Outstanding Junior (2010) and Senior (2015) Faculty Researcher Awards, as well as the Graduate Research Scientific Award for the best PhD dissertation. In 2012 she was honored by Mass High Tech as one of 20 Women to Watch in New England for technical innovation and leadership in the community. Other recognitions include being named to Foundry Management & Technology’s 2009 list of Metalcasting’s Next Generation of Future Leaders; the 2008 Orr Early Career Award and the Orr Best Paper Award from the Materials Division of the American Society of Mechanical Engineers (ASME); the Axel Madsen Award from the Center for Powder Metallurgy Technology; the American Foundry Society’s Aluminum Division Scholarship Award; and the ASM Worcester Chapter Chester M. Inman Award.

Lados earned BS and MS degrees in mechanical engineering at Polytechnic University of Bucharest, an MS in mechanical engineering at Southern Illinois University at Carbondale, and a PhD in materials science and engineering at WPI. She has published more than 85 articles and two book chapters, and has delivered over 280 conference and industrial presentations and invited lectures. She has two patent developments, one for a novel manufacturing method for metal matrix nano-composites and one for the integrated fabrication of polymer-metal composites with structural and functional properties using 3D printing.