One day, educators from the Sylvester Manor Educational Farm on Long Island will be able to show young students a working model of a windmill and share ideas on how to create renewable energy to power their greenhouse—all thanks to a team of students from WPI.

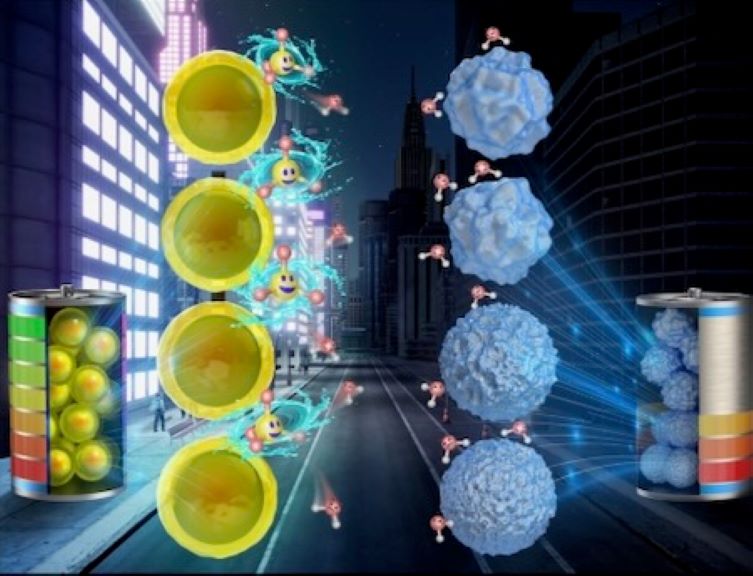

Five mechanical engineering students have been designing a modern wind energy system to augment restoration of a windmill built on the farm in 1810, as part of their Major Qualifying Project (MQP), a team-based, professional-level design experience that is the culmination of WPI’s project-based undergraduate education. The design will inform the farm’s administrators about what is needed for the windmill to create energy that could be stored in a battery and used to power something on-site, like the farm’s greenhouse.

The students also are creating a working model that educators can use on-site or in classrooms to teach school children about the historic windmill and renewable energy generation.

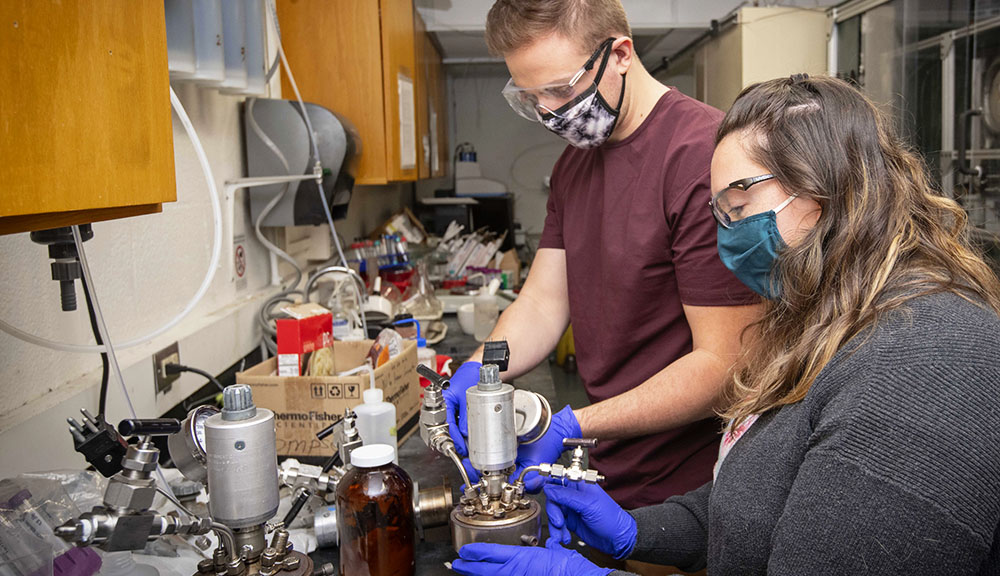

The MQP team includes Carly Campbell, Anna Carriero, Alaa Hassan, Brandon Weyant, and Georgianna Wood, all in the Class of 2020. Hassan and Wood are receiving both their bachelor’s and master’s degrees.

Despite having to work off campus in D-Term because of the COVID-19 pandemic, the team has been able to finish their research project, according to Harold Walker, Schwaber Professor of Civil and Environmental Engineering. Walker advised the project along with Brian Savilonis, professor of mechanical engineering. The team is making its final presentation to members of Sylvester Manor via videoconferencing and will arrange to get the model to the educational farm.

“This was an incredibly appealing project for us,” says Sara Gordon, who works on planning and sustainability at Sylvester Manor, a nonprofit organic farm, historic plantation, and education center on Shelter Island in Long Island, N.Y. “The students have advanced their study and discipline, and we’ve got information we can take to funders, regulatory partners, and manufacturers and say, ‘We looked at the energy production potential of this windmill and concluded this is what we need.’ This will help us start the conversation about how wind works and how it can be harnessed. All of this is absolute gold for us.”

Situated on 240 acres, Sylvester Manor is focused on teaching apprentice farmers, hosting student field trips and summer youth programs, and educating visitors about the history of food, labor, and American culture, as well as

modeling innovating practices and technologies to promote an understanding sustainability, including sustainable sources of energy.

The windmill, built as a gristmill to grind grain into flour, had ceased operating in the mid-1900s and its driveshaft had rotted. With its interior works otherwise in good condition, it is now being restored to once again grind grain grown on and off the farm.

The MQP team was charged with designing a modern wind energy system that could be incorporated with the windmill, capturing and storing sustainable energy for use on the farm.

The scale model—3 ft. tall and 1 ft. wide, with 10-in. blades—will include all the main functional elements of a full-scale system. Educators will use it to demonstrate how wind energy can charge a battery or power a light.

“From an educational perspective, this is a great project because it allows the WPI students to see how design is related to function,” says Walker.

“The windmill originally wasn’t designed to produce electricity; it was optimized to slowly move a grindstone,” he points out. “It’s challenged the students to understand where the losses are in a system and why this system might not be as efficient in converting wind energy into electricity as a modern system. It’s been enlightening. It gives the team a deeper understanding of the physics and mechanical aspects of a wind energy system.”

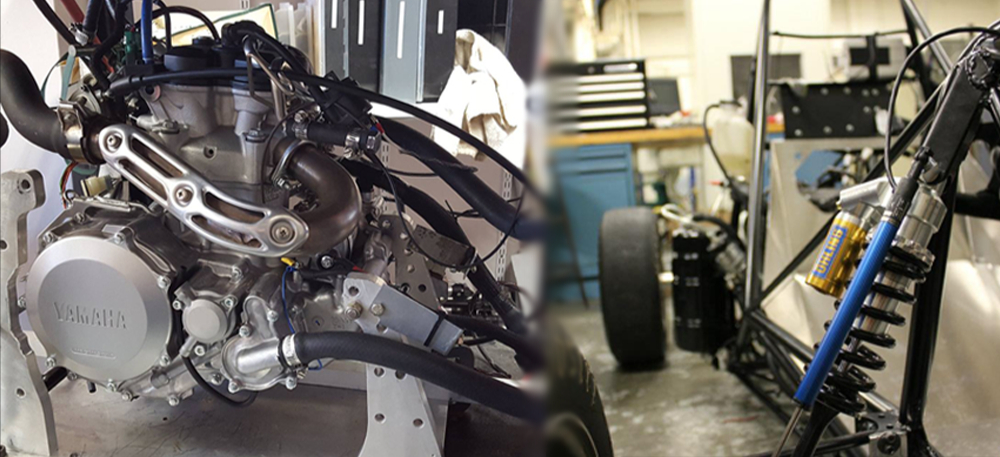

The team had to do a lot of analysis: calculating how much wind blows in that area of Long Island, how to introduce a modern electrical system into the 210-year-old windmill, how much energy the windmill might actually produce, and determining the best battery for storage. To build the model, they used 3D printing, laser cutting, and CAD software to create precision drawings.

“One of the biggest challenges we had was to find the balance between keeping it historically accurate and making it function,” says Wood. “There are a lot of old windmills not being used and this opens a lot of doors for them. Other windmills could do this.”

For Hassan, the biggest challenge wasn’t the engineering aspect of the project. “It was figuring out how to best work as a team,” she says. “We all had different ideas of ways to accomplish a task. It was about coming together and figuring out what was best.”

– By Sharon Gaudin