A chemical engineering professor at Worcester Polytechnic Institute (WPI) is applying innovative chemical engineering processes to develop tools that could aid farmers in rural areas and developing nations, establish improved water supply chains for municipalities, and spur improved drug development.

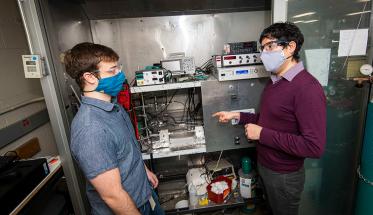

Andrew Teixeira, assistant professor of chemical engineering, has received four grants—including a prestigious National Science Foundation CAREER award—totaling more than $1.6 million over the past several months. He has received grants from three different agencies to study the issue: the National Science Foundation, the U.S. Department of Energy, and Mainstream Engineering Corporation. A common theme across the grants is the focus on chemical manufacturing to support on-demand water and agricultural efforts and domestic pharmaceutical drug manufacturing.

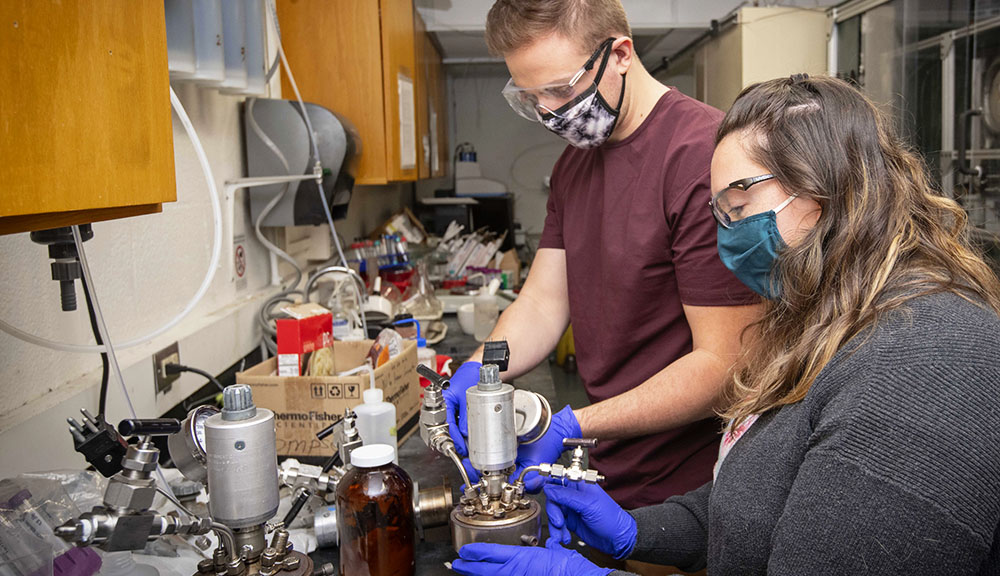

Teixeira’s approach is part of a new wave of manufacturing that aims to create a distributed chemical and energy landscape that transitions from large, centralized refineries to small, on-demand systems that use geographically localized resources.

“I’m very excited to help define a new paradigm in chemical manufacturing by introducing periodic, dynamic operating conditions,” said Teixeira. “There have traditionally been a limited number of tools to use when designing refineries, but now we’re proposing an entirely new strategy that allows us to unlock pathways that were previously unachievable.”