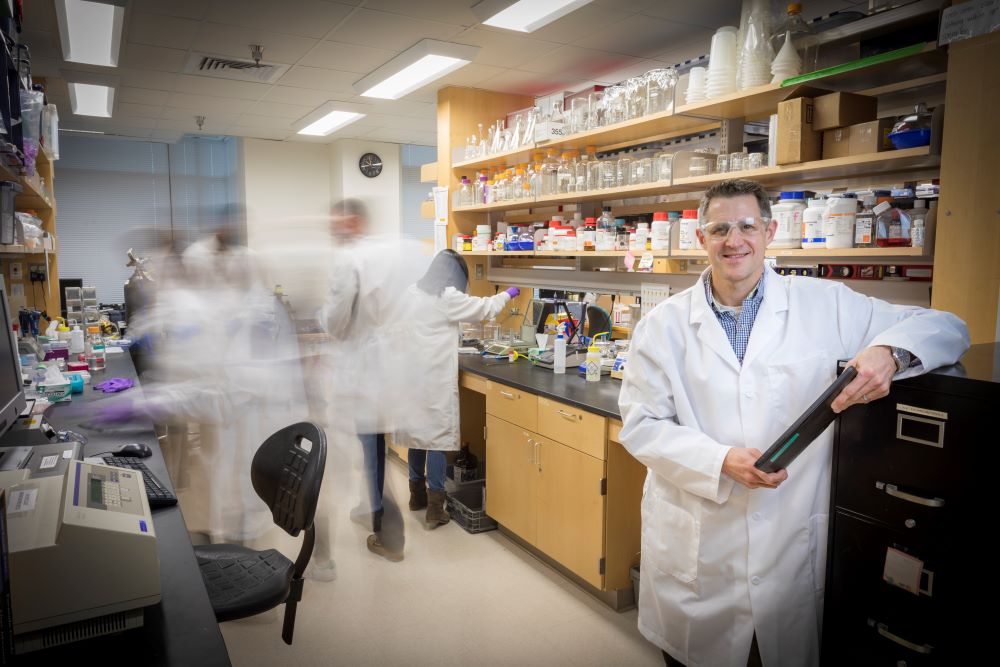

Yonghui Ding holds a 3D-printed scaffold

The tiny opaque tube that Yonghui Ding holds up to the light in his laboratory looks like a bit of debris from a dismantled ball point pen.

Just 1 centimeter long and about 2 to 3 millimeters in diameter, the biodegradable tube is too small for the grooves and channels on its surfaces to be easily visible. Yet those microscopic textures represent an advance that Ding, an assistant professor in WPI’s Department of Biomedical Engineering, thinks may someday lead to big improvements in heart bypass surgeries.

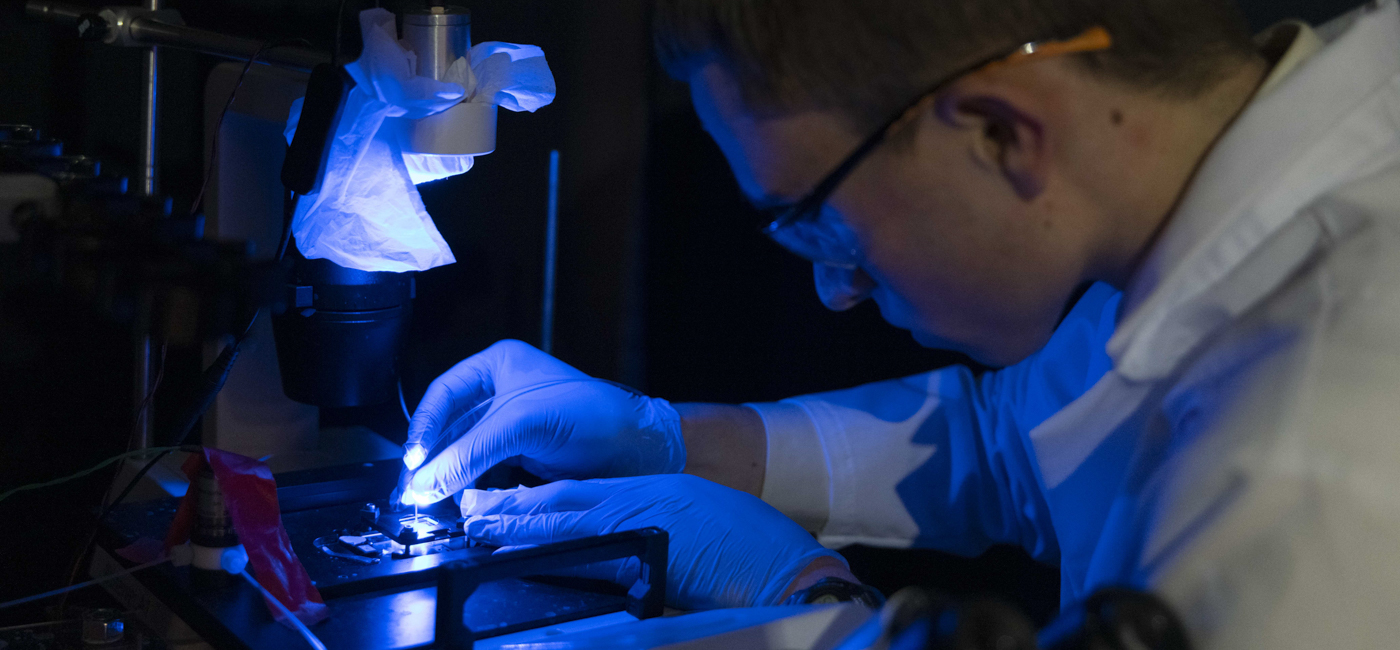

In a new paper in the journal Advanced Healthcare Materials, Ding and research collaborators from Northwestern University reported that they developed a rapid 3D-printing process using biodegradable “ink” and light to produce tubular implantable scaffolds with grooves and channels. The textures created pathways for cells to migrate across the implant’s surfaces and line up with each other, a critical step in regenerating blood vessels to the heart.

“The goal of this research is to regenerate arteries, not just replace them,” says Ding. “To achieve that goal, it will be important to develop grafts that temporarily provide the structure for tissue growth and enable new cells to grow into healthy and functional blood vessels.”

The research aims to improve surgical treatment for one of the nation’s leading public health challenges—heart disease. The leading cause of heart attacks is blockage in the vessels supplying blood to the heart. A common surgical treatment is coronary artery bypass grafting, which involves attaching a vein or synthetic tube to reroute circulation around a blockage to restore healthy blood flow to the heart.