Open to anyone in any area of study at WPI, the McDonough Makerspace and adjacent Fitzgerald Prototype Lab are available to the entire campus community. They are places to germinate ideas, test limits, refine details, and have fun.

Opened in 2018 in a glassy, industrial-feeling space on the ground floor of the Innovation Studio, the Makerspace filled in quickly with students on a recent afternoon.

Unloading freshly laser-cut pieces of wood from the nearby prototype lab onto a table, first-year student Adrian Ortiz Villagomez spread out his project and got ready for that night’s task: to create a “contraption” that makes it easier to feed a spool of vinyl for cutting. He said he hoped to complete the final piece of his puzzle that evening.

A few tables away, student workshop instructors photographed various items in a light box; they plan to compile an online library full of step-by-step tutorials on everything from sewing a bag to making stickers to using a CNC router cutting machine.

Students, faculty, and staff at WPI can use the space to work on personal or school projects, and after a brief safety training, they can use machines or check out tools. The space is intended to welcome all aspiring makers and foster a community where anyone can try their hand at building and creating. Users can check out basic hand tools and machines, and also have access to a powerful drill press and state-of-the-art 3D printers.

“It’s a way to drive engagement,” said Adam Sears, director of technical operations for the Innovation Studio. “We want to break that fear, that anxiety of entering a new space. We’re putting fun things out there for the community to get excited about building new skills and making valuable connections.”

Student-run spaces

Sears and Mitra Anand, the space’s advanced technology and prototyping specialist, lead the operation of the Makerspace and Prototyping Lab. But, as with many things at WPI, it has evolved into a partly student-run operation. Adam Murrison ’23, Jakob Sperry ’23, Cameron Wian ’25, and Sydney Kerivan ’25 coordinate the 75 to 80 workshops that run over the course of a term.

Murrison said one of the goals from the beginning was to create a program that allowed users to develop skills that might not be directly related to their fields of study, but would provide intangible benefits. Students can make prototypes for an IQP (Interactive Qualifying Project), or they can make holiday gifts for family members back home. Workshops for sewing, leatherworking, and jewelry making are popular offerings.

With Sperry and Kerivan, Murrison works with a crew of instructors to keep everything running. Three of those student instructors—Maya Evohr ’ 25, Yan Acevedo, and Nicole Duong ’26—took pictures of fabrics and tools and hovered over a sewing machine in the Makerspace on a recent evening. They were documenting the steps involved in a sewing workshop to develop tutorials for those unable to attend.

The workshop teaches participants how to make items from lanyards to scrunchies to the drawstring bags that, at the moment, were bathed in the light of the sewing machine.

“I think this needs to be photographed,” Evohr said as she stopped the machine’s needle for a moment. When she and her team are finished, users will be able to bring up the instructions on a smart phone and guide themselves through the process. Don’t know anything about using a laser cutter or a sewing machine? That’s fine. Evohr, Acevedo, and Duong pointed out they had no real expertise in sewing before they started coming to the Makerspace.

As Acevedo and Duong paid close attention, Evohr made some last-minute calculations before sending the thread through. “Sew an inch, leave half an inch,” she said.

Ties to value creation, innovation, and entrepreneurial mindset programs

Curtis Abel, executive director of WPI’s Innovation and Entrepreneurship Center, said that the integration of maker and prototyping experiences with other entrepreneurial mindset initiatives like TinkerBox, MakerBucks, and Value Creation brings together an inclusive community around shared passions to explore their creativity, test new ideas, and quickly iterate on their designs. This culture inspires students to pursue their ideas.

“It goes beyond getting your hands dirty,” Abel said, adding that students tinker, learn from each other, and learn how to ask the right and well-posed questions to solve ambiguous problems in a unique way that people care about. “They experience new forms of collaboration and develop career-distinguishing skills that can be applied to any life situation.”

TinkerBox and MakerBucks, two programs focused on fueling student curiosity, offer funding and mentoring to students to turn their one-offs and brainstorming sessions at the Makerspace into viable products.

“Our goal is to build a diverse and inclusive community by fostering partnerships with students. While every student’s journey is unique, the MakerBucks and TinkerBox programs are designed to complement one another by providing opportunities for students to work on their passion projects, hone their entrepreneurial mindset skills, and build the community,” said Kristie DeJesus, senior director of innovation and entrepreneurship.

DeJesus said TinkerBox projects often evolve beyond campus borders; she pointed to Kemal Rifky ’25, whose TinkerBox idea turned into 360 Energy, a company dedicated to providing clean electricity to rural areas of Indonesia by deploying low-cost hydroelectric microgrids.

MakerBucks is a similar program, but serves as more of a stepping stone to get projects to the next level. It focuses on reducing barriers to entry and gives students up to $200 to work on projects that could survive the more rigorous TinkerBox program.

The Makerspace and Prototyping Lab are busy, fun, and welcoming spaces, but they also reflect a commitment to solving problems that matter to others, Abel said. “They provide a culture that enables innovation and start-ups to flourish” he said. “We want students to enter into a world of curiosity and discovery, and to be inspired."

Integrating this with WPI’s Value Creation Initiative brings innovation to life through immersive experiences. Students practice the fundamentals of “how” to solve problems that matter to others with extraordinary value in a safe, inclusive, positive, and fun learning environment.

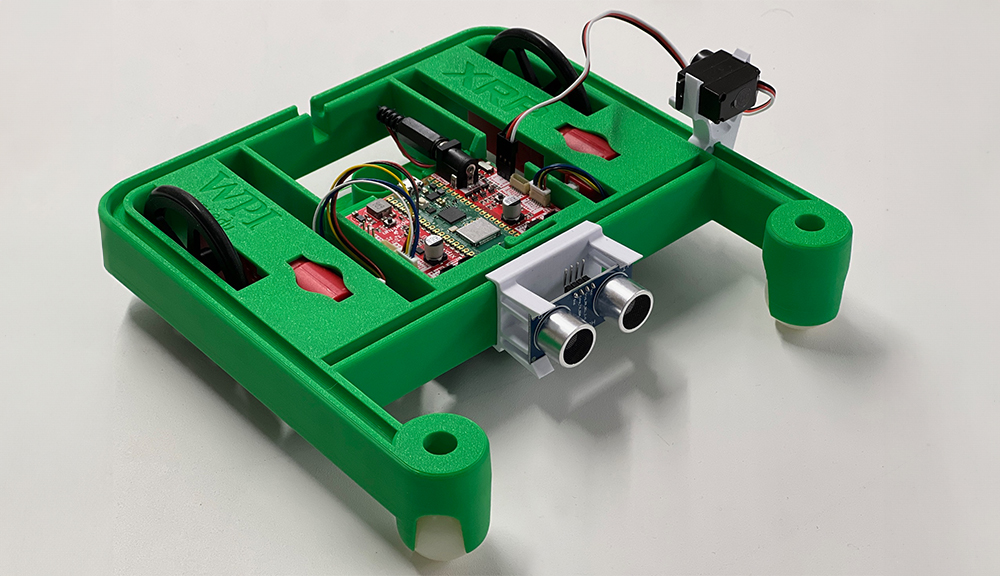

Team helped produce robots for First Global event in Geneva

The Makerspace and its staff occasionally get tapped to help with other WPI projects. For example, in the rush to get hundreds of XRP robot prototypes ready for their international debut at the First Global Challenge in Geneva, Switzerland, last fall, students and Prototyping Lab staff ran 3D printers around the clock.

“We were under the gun,” Anand said. “We were discovering kinks in the system live, while doing 3D printing in a mass-production type of environment.”

Murrison said the overriding theme of the Makerspace is accessibility. It doesn’t matter what your major is, and it doesn’t matter what labs you may or may not have access to—the space is designed to break down traditional silos and open up hands-on making to everyone at WPI.