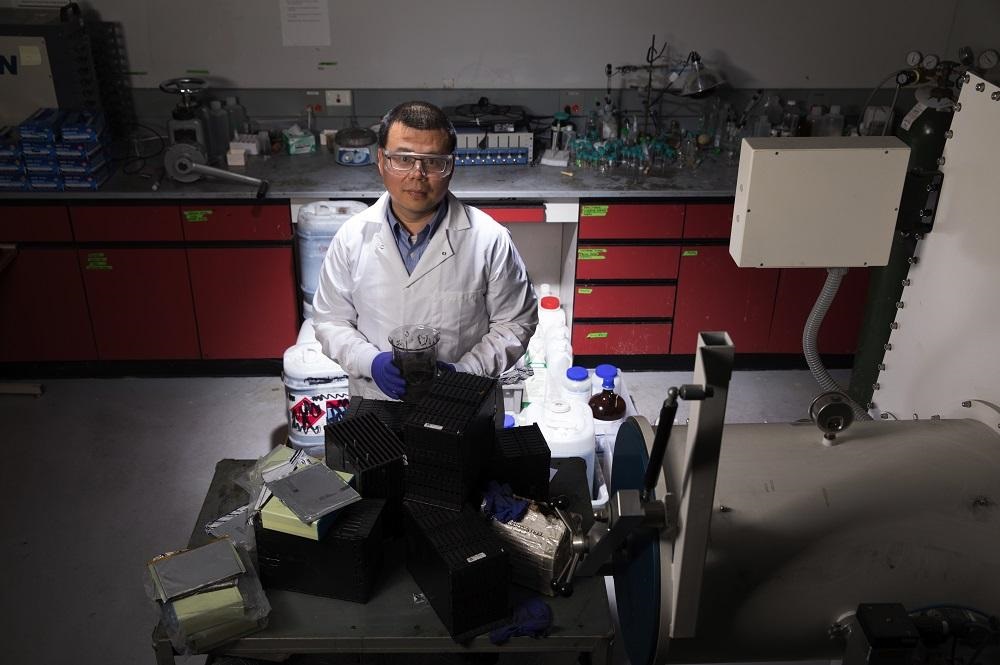

Worcester Polytechnic Institute (WPI) will expand its work on lithium-ion battery recycling and lead a team of academic and industry collaborators in a $2 million project to lower the cost and improve the performance of recycled battery materials so they are comparable to new materials.

The project will be funded under a 50% cost-sharing agreement with the United States Advanced Battery Consortium LLC (USABC). Battery developer A123 Systems LLC and Battery Resourcers Inc. have been selected by WPI as subcontractors for this project.

The three-year initiative will build on two previous projects that developed technologies to recover materials from spent batteries.

“Previously, WPI, A123 and Battery Resourcers have successfully recovered NMC cathode materials from diverse spent lithium-ion batteries,” according to Yan Wang, WPI mechanical engineering professor and lead researcher. “Over the next three years, we will improve the recycling process to recover high nickel cathode materials and further lower the cost of recycled materials.”

Bringing down the cost of recycled materials matters because lithium-ion batteries represent a significant cost in the production of electric vehicles. The U.S. Department of Energy has established aggressive goals for industry to lower the cost of lithium-ion vehicle batteries.

About USCAR

USABC is a subsidiary of the United States Council for Automotive Research LLC (USCAR).

Founded in 1992, the goal of USCAR is to further strengthen the technology base of the domestic auto industry through cooperative research and development. For more information, visit www.uscar.org.

All USCAR Member companies have joined in becoming signatories of the Responsible Raw Materials Initiative (RRMI, now part of the Responsible Minerals Initiative, RMI) Declaration of Support.