Brown has long been interested in preventing sports injuries. An All-American skier as an undergraduate at the University of Vermont in the early 1970s, he went on to do his graduate studies there. He worked with an orthopedics research group, who found an alarming increase in ACL injuries among skiers. In 1983, they presented a study on a new skiing-specific mechanism for ACL injuries to the International Society for Skiing Safety.

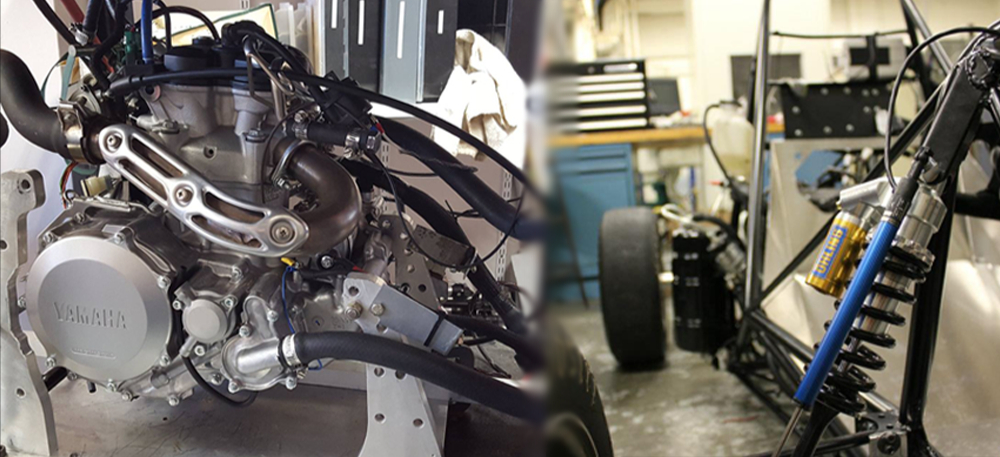

To develop early prototypes, the WPI team used a band saw to slice the sole horizontally, and install a low-friction interface where the load transfer is controlled by the goat’s head springs.

The shoe design, for which WPI has received an initial U.S. patent, has captured the attention of longtime entrepreneur Ed Cowle, an angel investor and CEO of New York-based Sports Engineering, Inc. (SEI).

SEI has invested in excess of $400,000 in the shoe project, which is helping support research by undergraduate and graduate students and development of a prototype. SEI has an exclusive license to the patent as well as future intellectual property from WPI. WPI holds equity and will receive royalties on the shoe.

Cowle believes the invention addresses a gap within the shoe industry. “There’s not a lot of technical innovation in the athletic footwear space,” he said. “This disruptive technology fills a specific need, given the increasing number of ankle and knee injuries in sports.”

The basic mechanism and components can be adapted to shoes specialized for many different sports. Additionally, this platform technology could potentially be added to footwear used in hiking, rehabilitation, and other activities.

Jessica Shelsky, who received a bachelor’s degree in biomedical engineering and mechanical engineering from WPI in 2012 and a master’s in mechanical engineering in 2014, was a member of a student team, advised by Brown, that developed the shoe’s original design. “It was an amazing experience to be a part of a project from the early concept phase all the way to the first prototype developed,” she said.

She said the other members of her project team, Michael Doyle ’12 and Nicholas Workman ’12, brought various strengths to the effort. “Without this diverse group we would not have been as successful in developing a solution that could be patented and further developed,” said Shelsky, who now works as a senior manufacturing engineer for a medical technology company.

Todd Keiller, director of Intellectual Property and Innovation at WPI, said he is impressed with the project’s business scope and health benefits. “This is a student project that has attracted angel funding, which is bridging the development gap between what a shoe company is willing to invest in versus the stage of our original prototype,” he said. “It will be great to see a student project turn into a product on the market that will hopefully protect many athletes.”

Twelve undergraduates worked on the project this summer, funded through the investment from SEI. They are seniors Alex Alvarez (aerospace engineering) from Sellersville, Penn., Kyle Mudge (biomedical engineering and mechanical engineering) from Cumberland, R.I.; Tristin Carlton (mechanical engineering and materials science) from Coventry, R.I.; Ben Aldrich (biomedical engineering) from Rumford, R.I.; Julia Dunn (biomedical engineering) from Jericho, Vt.; Paula Sardi (mechanical engineering) from Cali, Colombia; Ethan Shipulski (mechanical engineering) from Hanover, N.H.; junior Josephine Bowen (mechanical engineering) from Lunenburg, Mass.; sophomores Eric Motler (mechanical engineering) from Albany, N.Y.; Colin McNamara (mechanical engineering) from Arlington, Mass.; Nate DeSisto (mechanical engineering) from Orono, Maine; and Mary Kandaras (mechanical engineering) from Arlington, Mass.

WPI graduate students working on the project are Allysa Grant ’18 from Framingham, Mass., and Jimmy Muller ’18 from Medford, N.J. Additionally, WPI has had the support of three students from École Nationale d’Ingénieurs de Saint-Étienne (ENISE) in France; Corentin Roland, Valentin Delache, and Axelle Vialette.