Advanced Sustainable Materials & Manufacturing

Materials Reimagined for a Sustainable Future

With a rich history in materials and manufacturing research and a modern emphasis on sustainability, WPI is a leader in discoveries that move beyond steel and alloys. Researchers working under the banner of Materials Reimagined, or MatR, are using computational modeling and materials characterization and design to make breakthroughs in advanced concrete, sustainable water, new energy sources, battery recycling, and more.

Research at WPI

Metal Processing Institute

The Metal Processing Institute is the largest industry-university alliance in North America and conducts research at the Advanced Casting Research Center, the Center for Heat Treating Excellence, the Center for Resource Recovery and Recycling, and the Center for Materials Processing Data.

Honeywell Aerospace

WPI and Honeywell Aerospace are working on hydrogen fuels that could power the next generation of aircraft.

Facilities

Sagamore Labs

WPI’s 20,300-square-foot Advanced Manufacturing Center at 15 Sagamore Road is home to modern laboratories where researchers are working on additive manufacturing, clean battery production, industrial drying technologies, and more.

Metal Processing Labs

Labs focused on metal processing are housed in the Washburn Shops, with resources that enable researchers to explore the design, characterization, and processing of new materials.

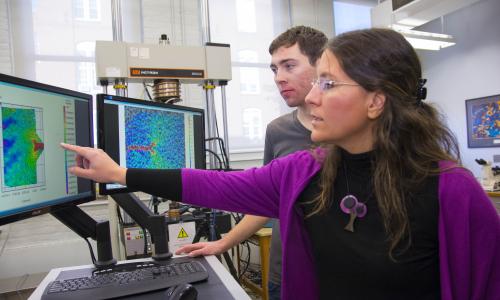

Materials Characterization Lab

The Materials Characterization Lab provides instruments for electron microscopy (SEM, TEM), x-ray diffraction, optical microscopy (conventional and inverted), physical property determination (hardness and micro indentation hardness), and materials processing (specimen preparation, heat treatment, metal evaporation and sputtering).

Integrative Materials Design Center

The Integrative Materials Design Center offers access to specimen preparation and characterization tools, cutters, polishers, optical microscopes, and more for the design of high-performance and sustainable materials.

LEAP

The Lab for Education and Application Prototypes is a partnership between WPI and Quinsigamond Community College. LEAP @ WPI/QCC houses equipment and facilities needed to prototype integrated photonics devices and develop the workforce that will manufacture them.

The WPI Expert Database

Meet our WPI experts and senior administrators who are leaders in a wide range of fields, and are available to offer ideas, opinions, analysis, and commentary. From issues facing higher education to current events, trending topics, and breaking news, our WPI profiles contain detailed information to help members of the media find the most appropriate person for their needs.