In an effort to increase WPI’s reach and engagement, the university recently showcased faculty and student research projects during Innovation Day at the Seaport facility.

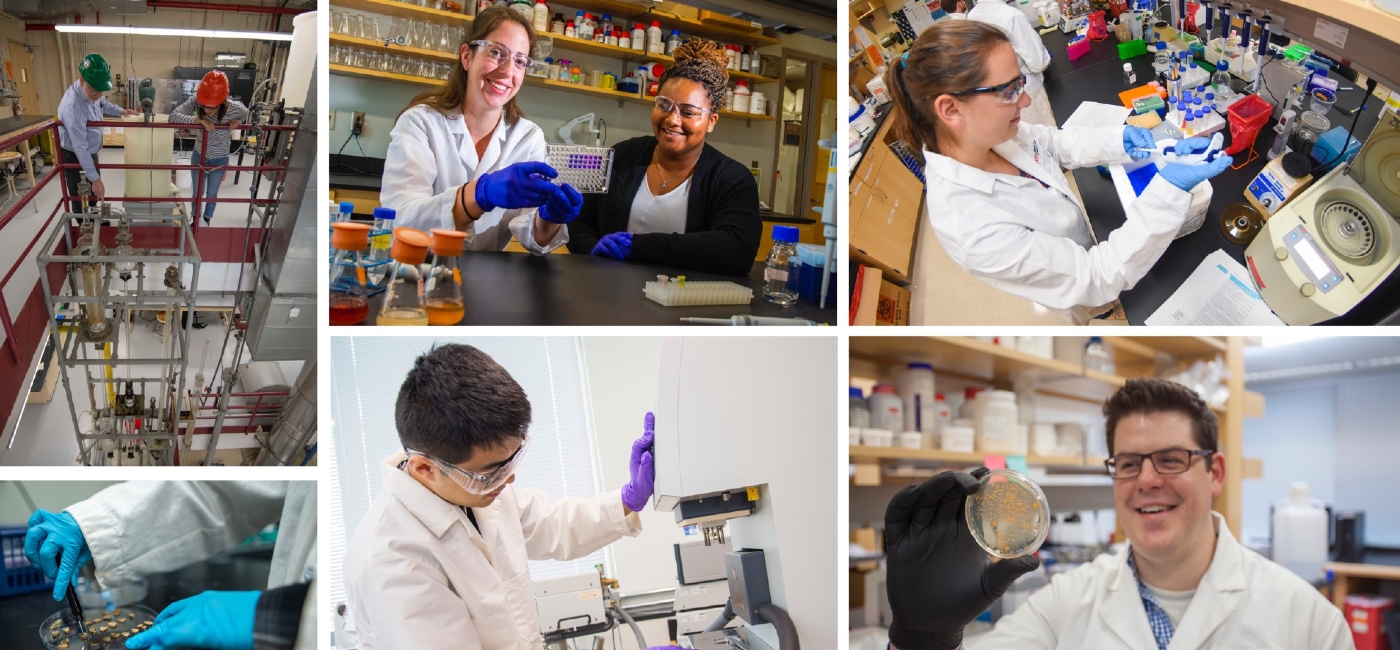

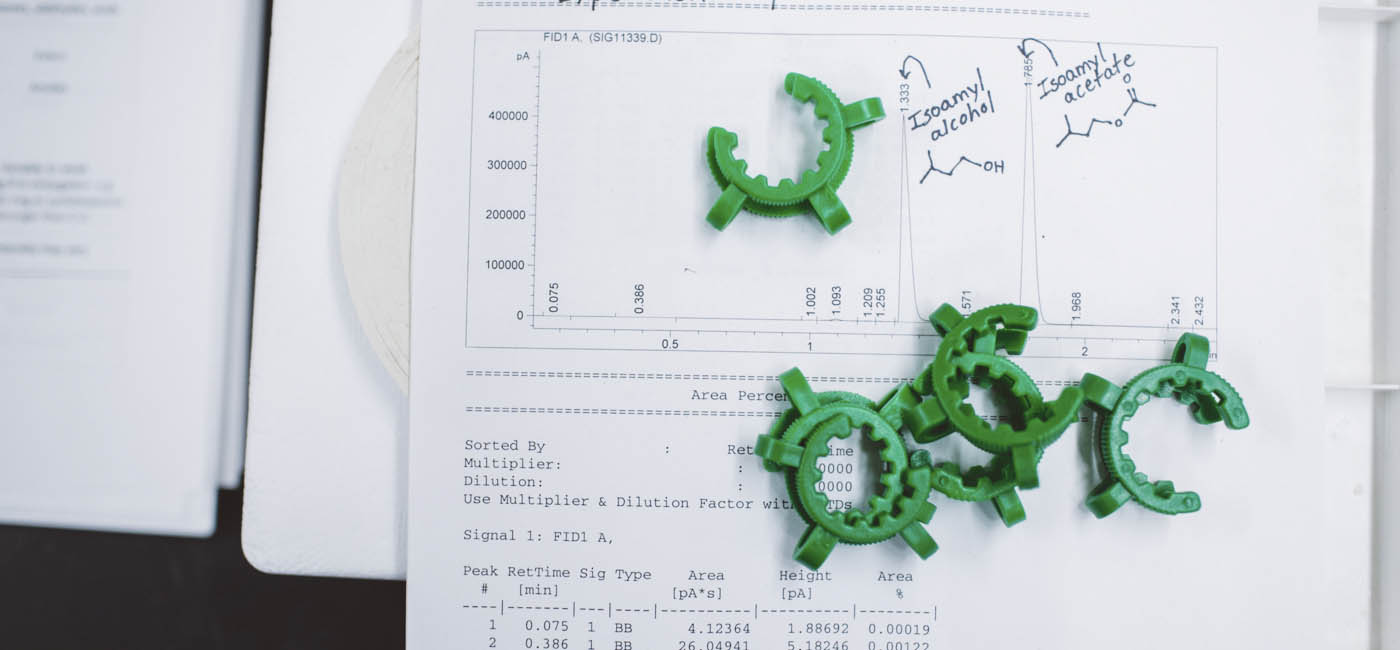

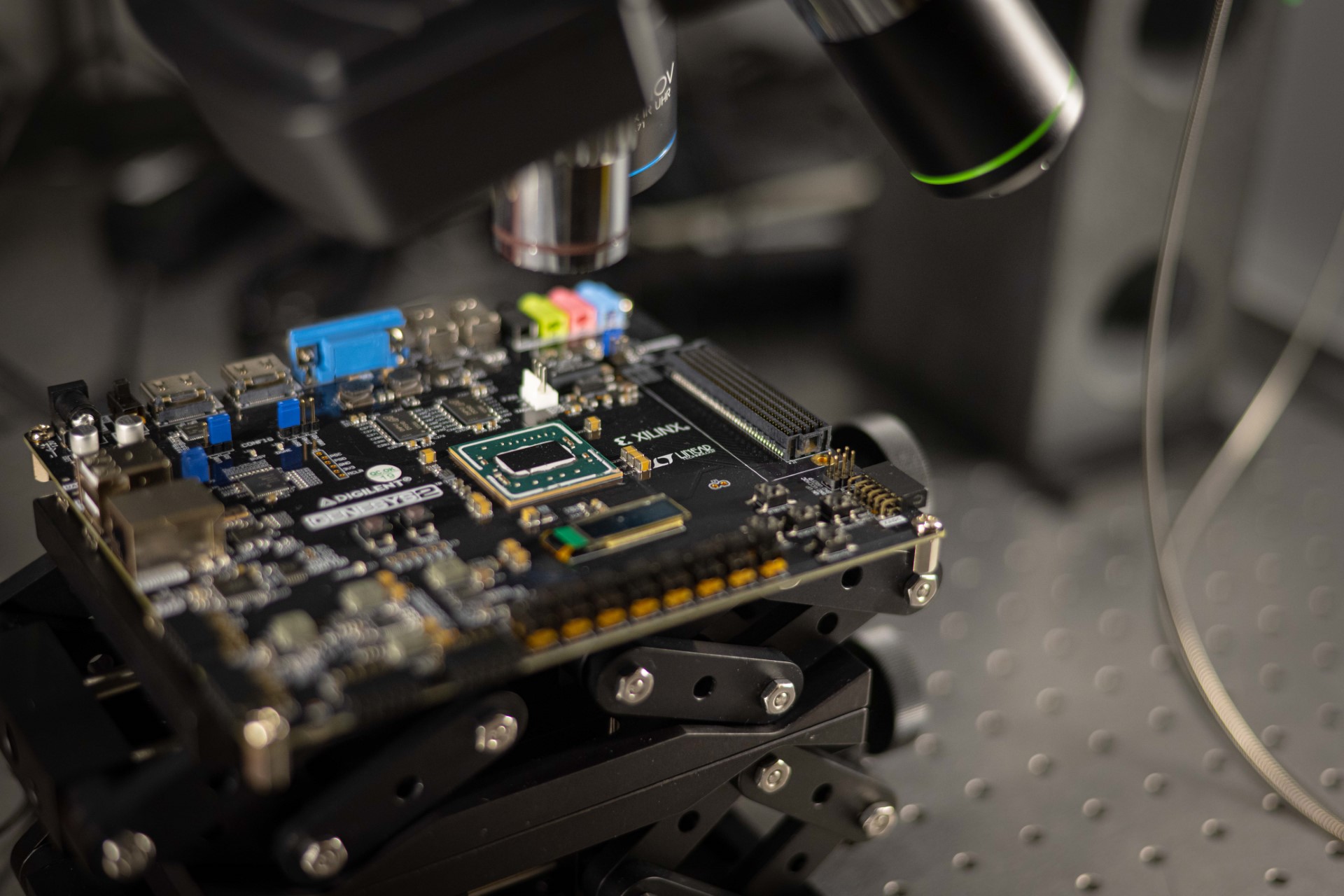

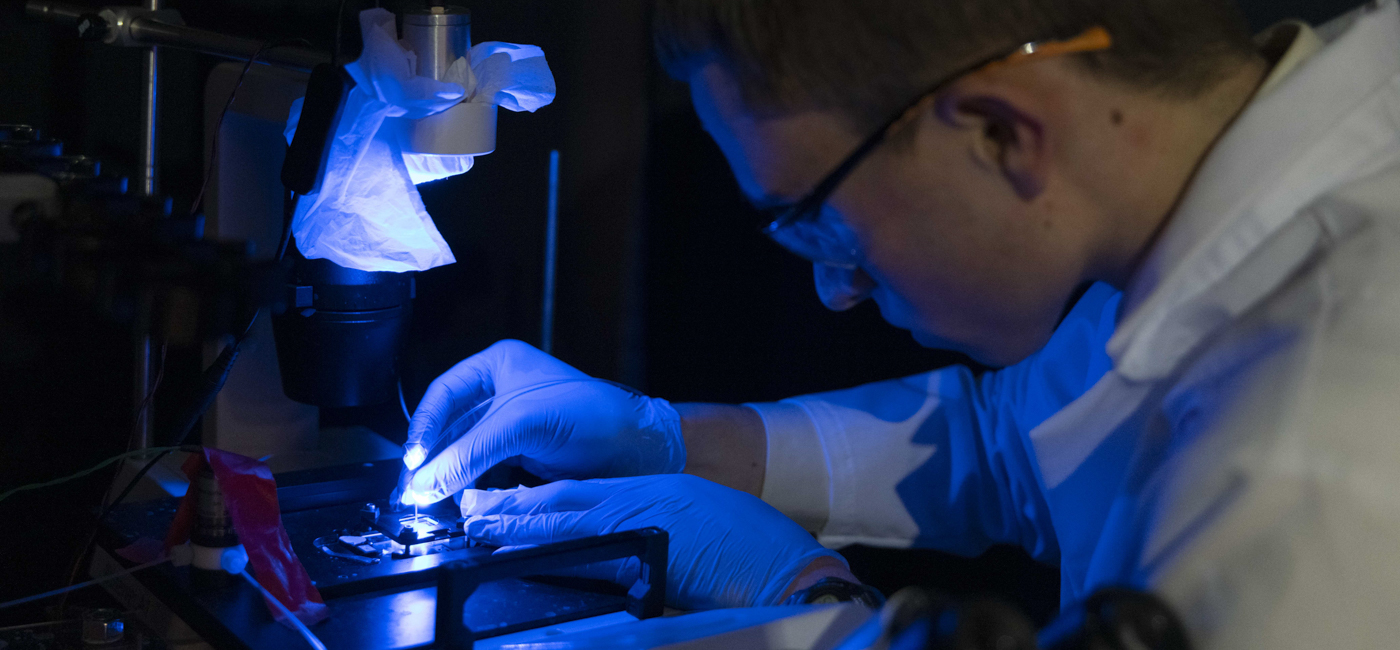

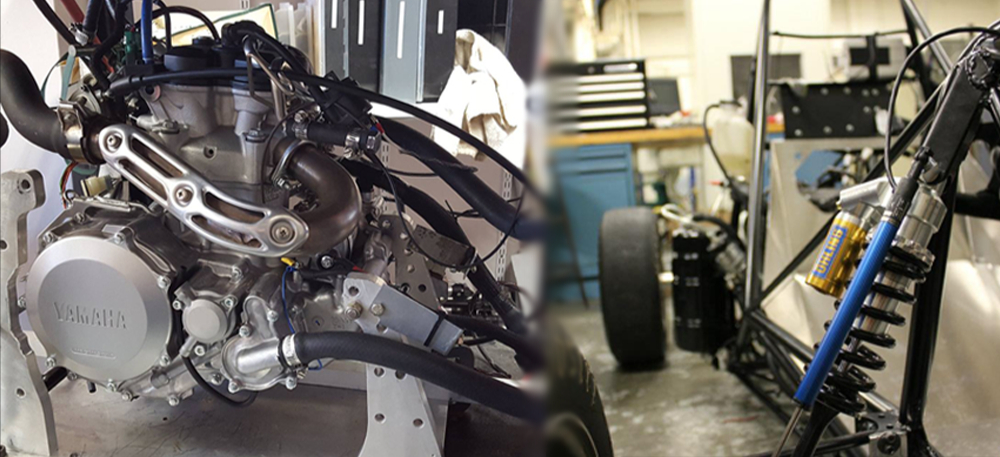

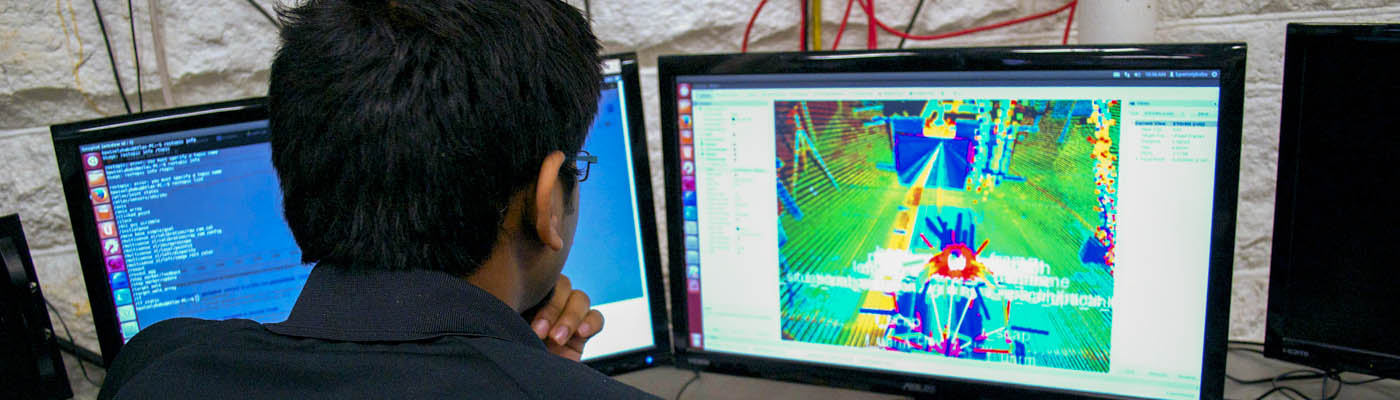

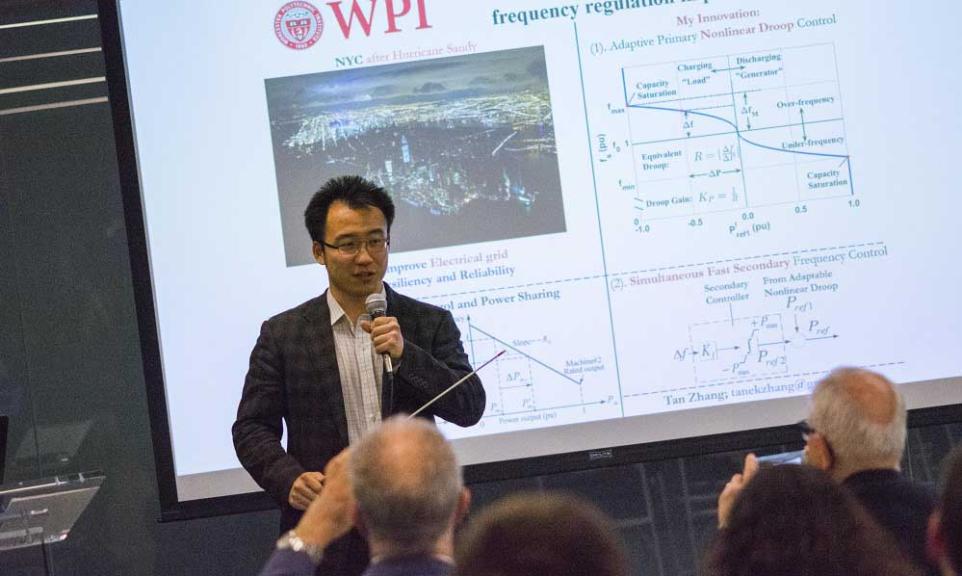

The program featured 14 short presentations for projects as varied as wearable sensors to prevent skin ulcers, an assistive device for drop foot patients, a gyroscopic shoulder prosthesis for arm amputees, enzyme-driven repair of damaged concrete, and an adaptive converter for improved electrical grid reliability.

Todd Keiller, director of intellectual property and innovation, explained that similar programs have been held in Worcester at the university’s Venture Forum. “The impetus there was, how do we expose early stage technologies to the communities and network to find commercial homes for them?” he said. “So, here at the Seaport space, if we can get one or two good leads—and we have one already who wants to engage in a licensing discussion—it’s a total win for us. Since it worked in Worcester, we said we would try it here.”

Keiller said the event fits into the university’s strategy for the Seaport space. “Many of the people walked here, and would not have driven out to Worcester,” he explained. “If we can do it in Worcester and here, we’re going to get different audiences that may work for the same goal.”

Bogdan Vernescu, vice provost for research, said the earlier Worcester forums were successful in matching students who have intellectual property ideas with venture capitalists and companies. “We wanted to do the same thing here,” he said. “This is the first time doing it, and we are going to continue to create a regular attendance at these events in Boston so we can expand the reach that WPI research has beyond the Worcester area.

“We assume there is a lot of capacity, due to all the universities in the area,” Vernescu said. “The assumption right now is that there is more capacity than the local universities can offer. We’re filling in a gap.

“This is one of the types of events that we will see more of in the Seaport." He added, "We’ll repeat this a few times a year. We hope to become more visible here, to make our research more visible, but also to bring companies back to Worcester to work with our students.”